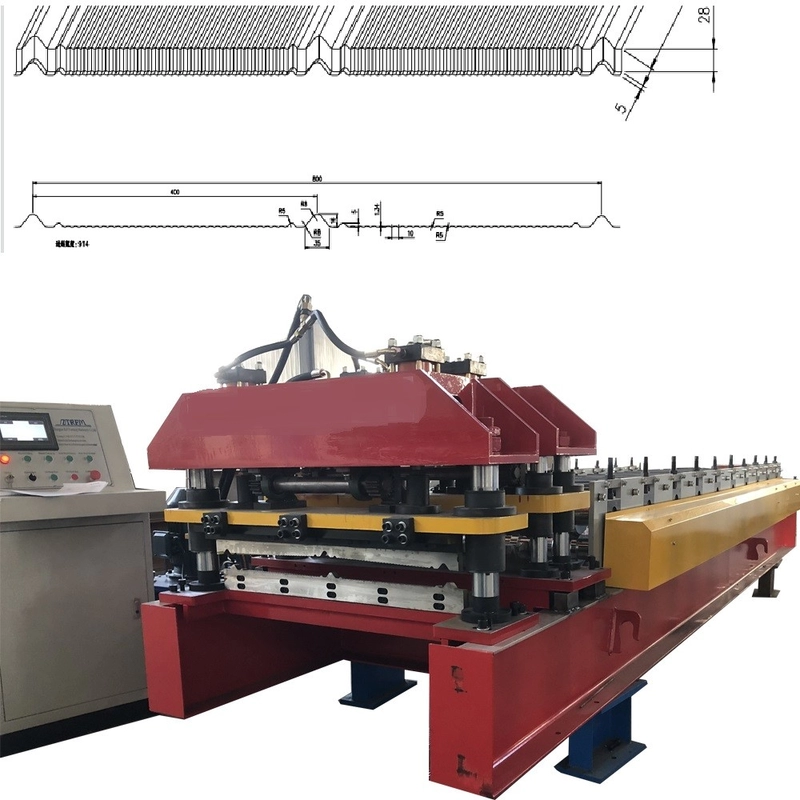

Zhongtuo Fully Automatic Steel Coils Cut To Length Line

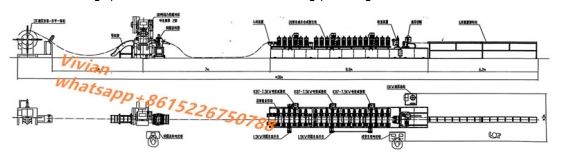

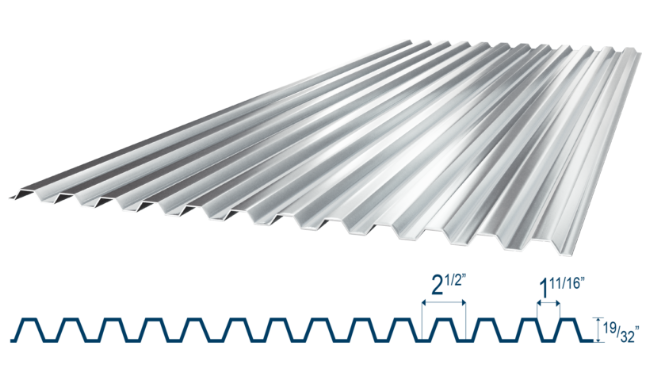

A cut to length line is a crucial piece of equipment in the metalworking industry. It efficiently cuts metal coils or sheets into specified lengths with high precision.

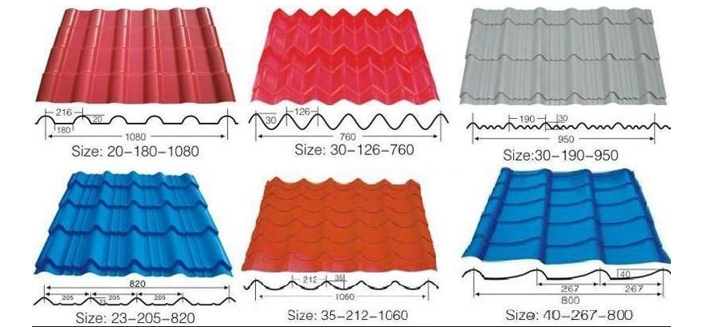

This automated system streamlines the manufacturing process, reducing manual labor and material waste. By using advanced measuring and cutting technologies, it ensures consistent, accurate cuts, meeting the strictest industrial standards. Ideal for various metals, from steel to aluminum, cut to length lines play a vital role in applications ranging from automotive parts to construction materials.

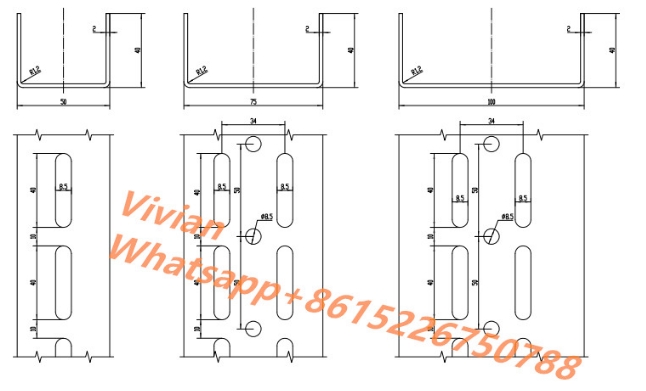

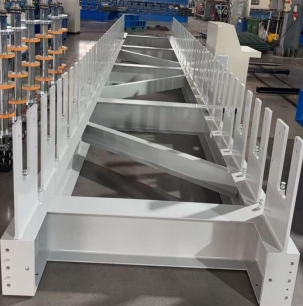

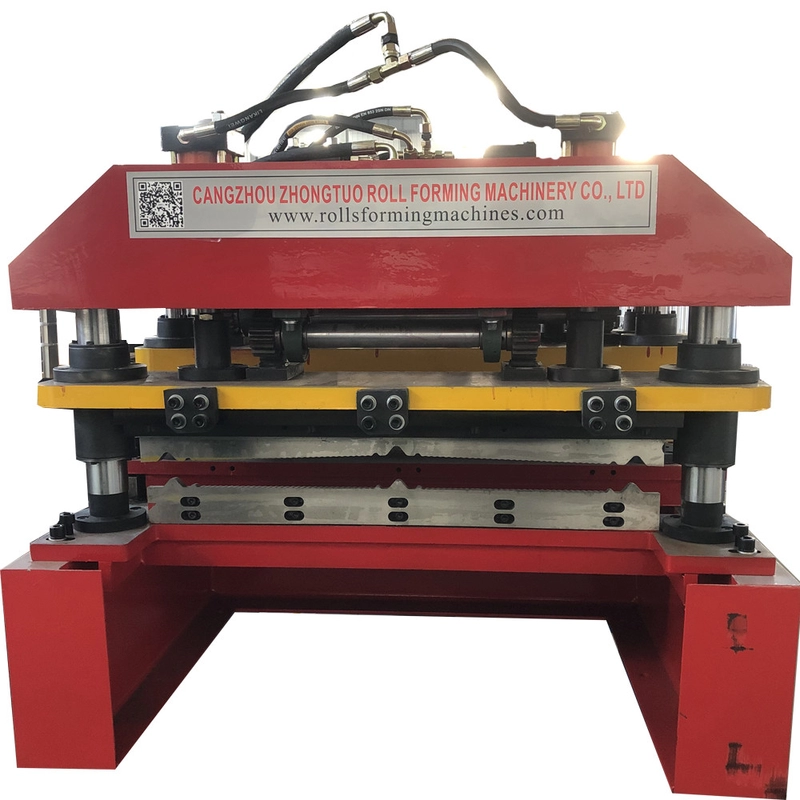

Zhongtuo cut to length line is composed of four parts: a hydraulic decoiler, levelling and cutting devices, a conveyor, and an automatic stacker.

The advantage of the Zhongtuo cut to length line:

- Our machine has with 10t loading capacity decoiler, and our decoiler has more functions, such as the loading cart, pneumatic brake, and hydraulic press arm (this is necessary especially for the 2.0mm thickness coils. And our decoiler has the hydraulic support holder, which can let the decoiler work more stably. Here I attached photos with you.

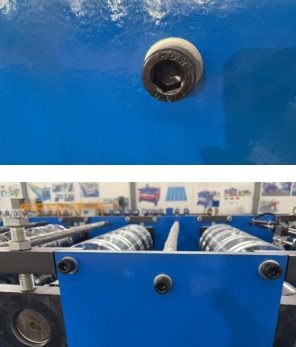

- Our machine adopts gearbox transmission type, which is more stable and at the same time, life lifetime is longer. If the machine adopts chain transmission, then after a period of time, the chain will loosen, and the customer will have to change the chain. And if the chain is loose, then the machine can not guarantee the cutting precision.

- Our machine adopts both top and bottom rollers for active leveling, which is better for the leveling precision.

- There are motors on the top of our machine, which can adjust the roller gap much more easily when you process different thickness sheets.

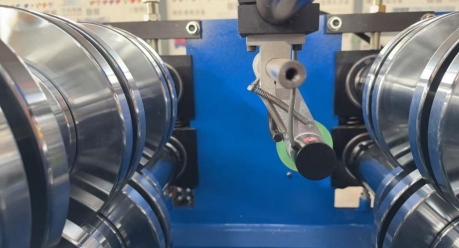

5. The guide rollers can guarantee the slitting precision. And much easier for adjustment at the same time, not hurt the material.

Dec. 16th 2025

Dec. 16th 2025