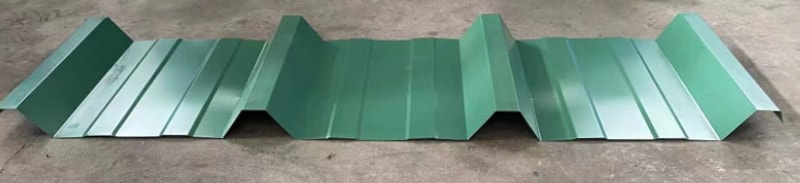

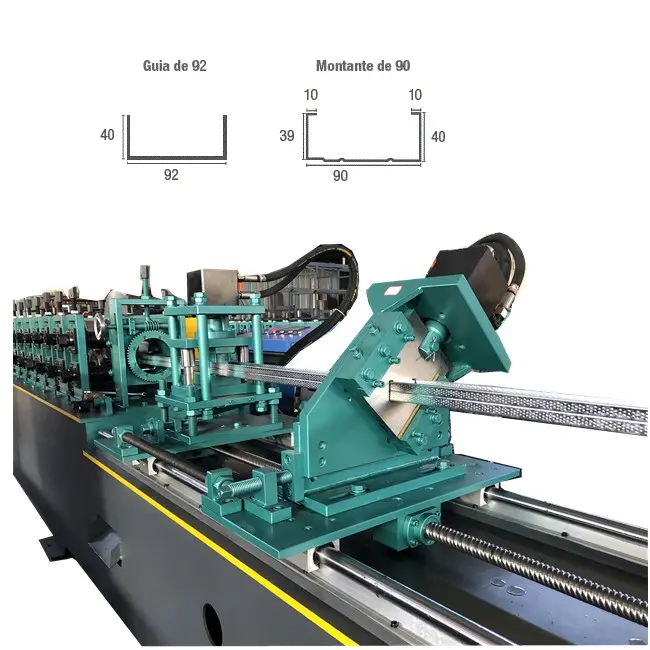

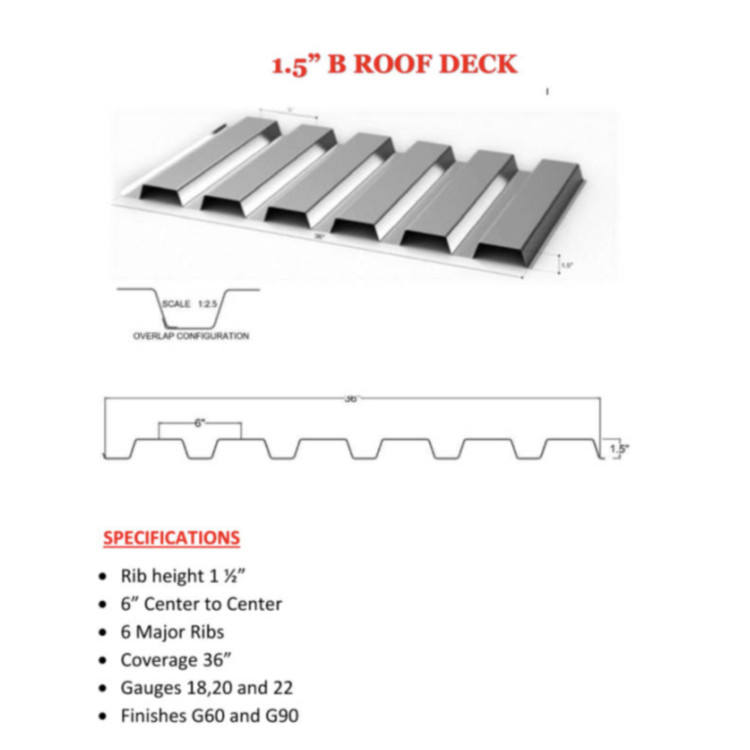

Tr 4 Roofing Sheet Roll Forming Machine Making Roofs For Peru Market

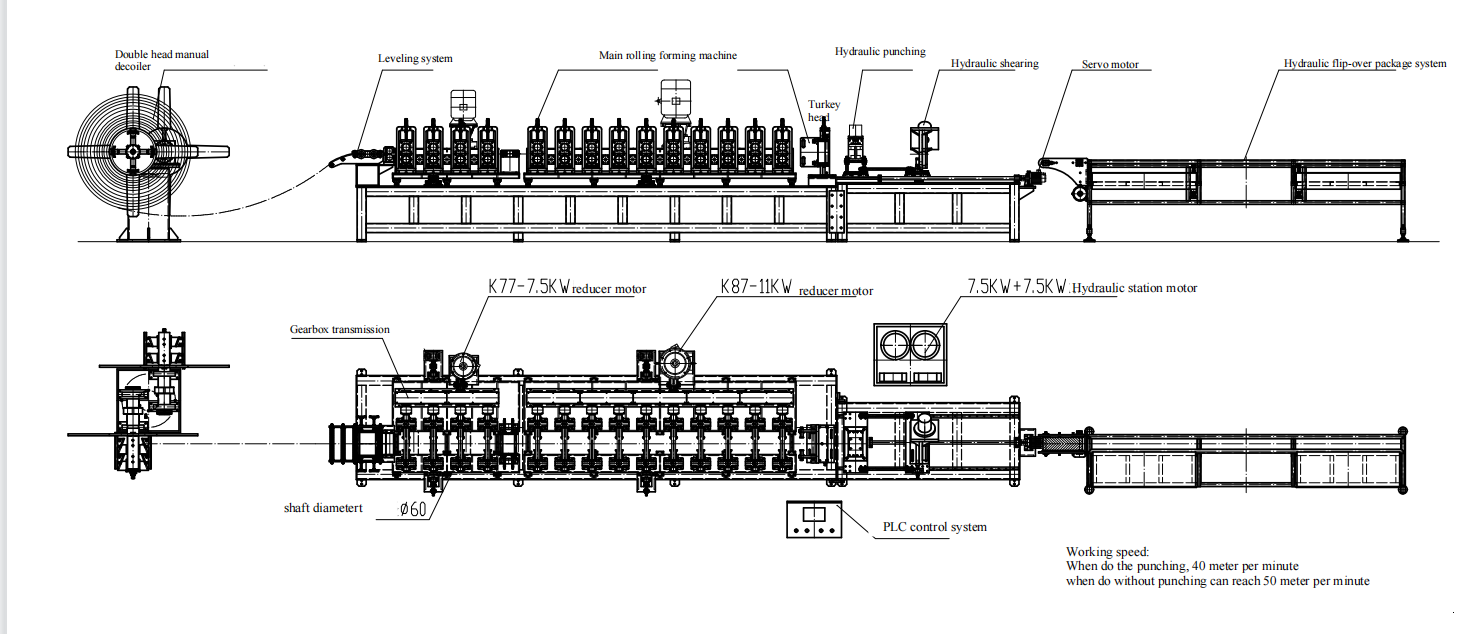

Advantages:

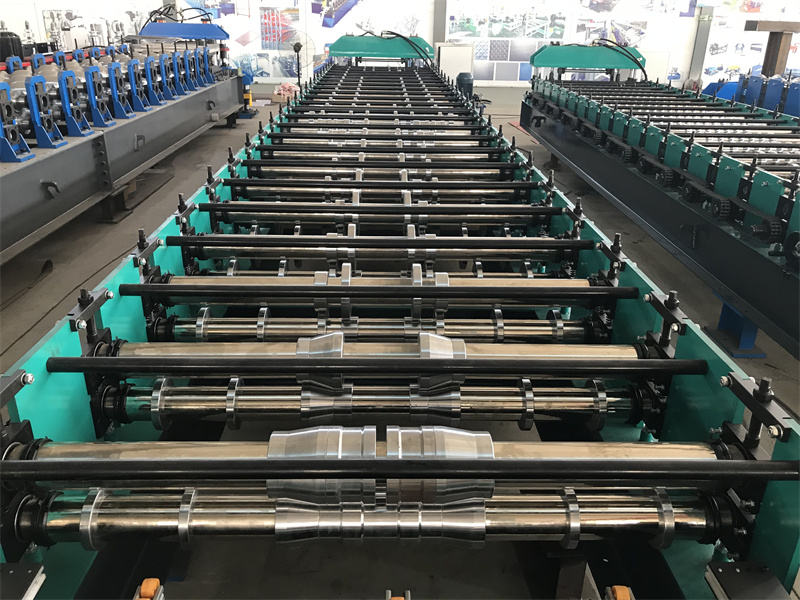

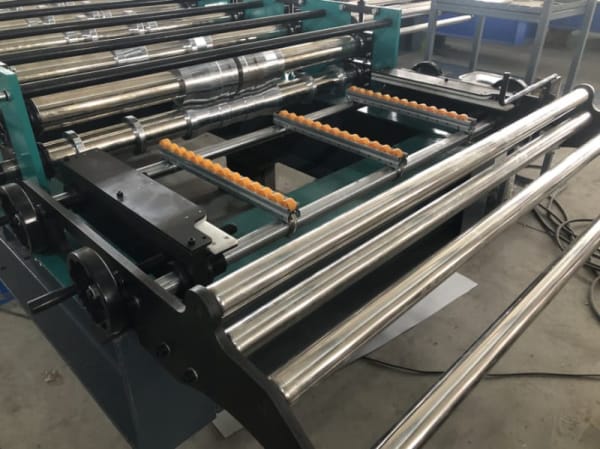

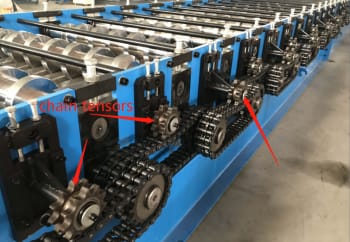

Stable Transmission: Double chain and gear drive,keynote rollers design.

Easy Operation : Easily set orders on the PLC control cabinet , easy, and fast

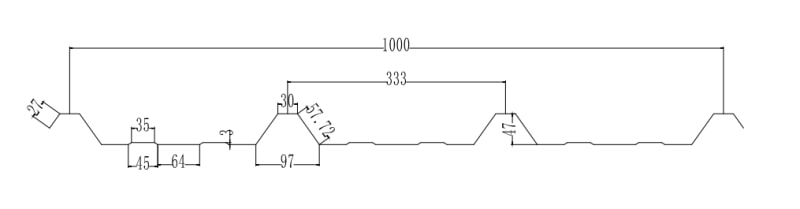

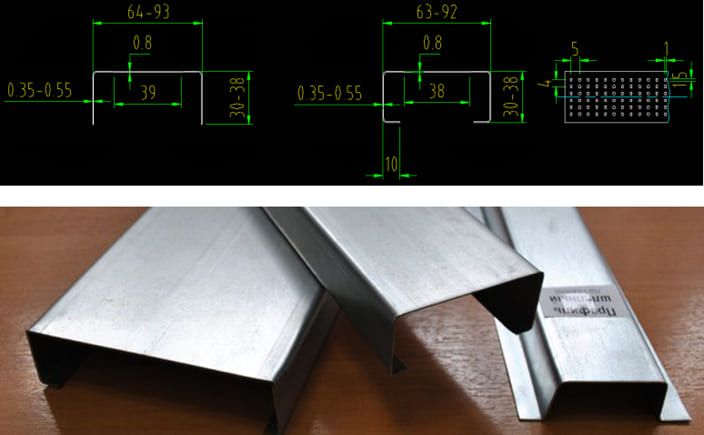

Tr 4 Profile drawing for reference:

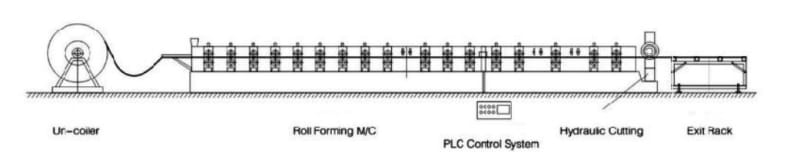

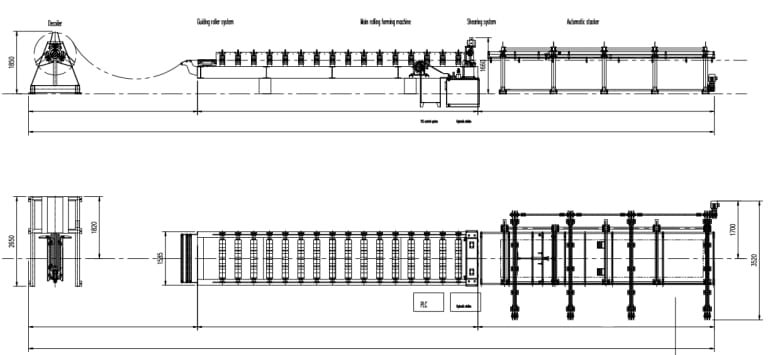

Machine Working Flow:

|

Tr 4 Roofing Sheet Roll Forming Machine Making Roofs For Peru Market

|

|

|

Raw Material

|

PPGI,PPGL

|

|

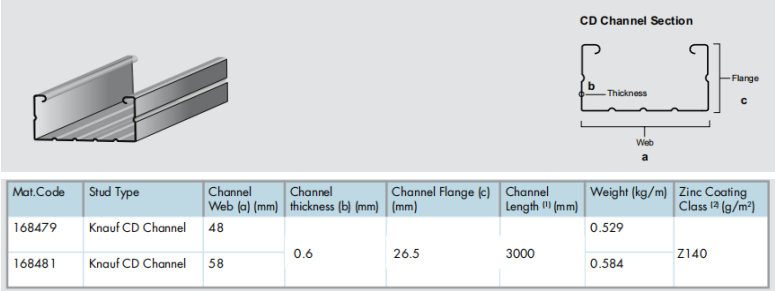

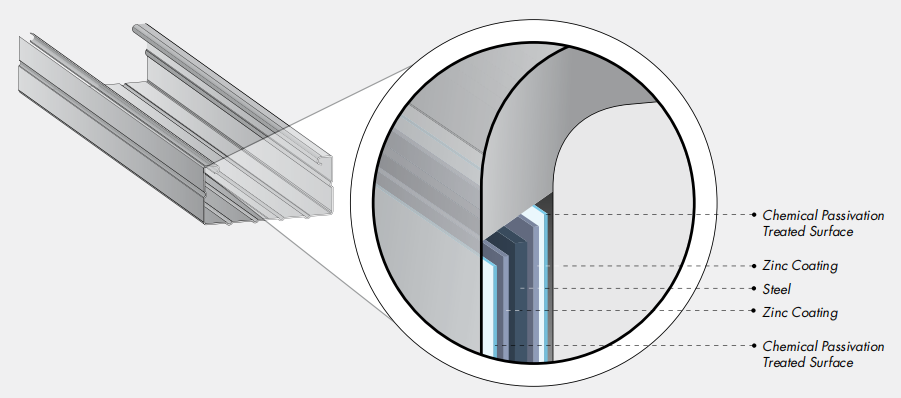

Material Thickness:24/26 Gauge (0.4-0.6 Mm)

|

|

|

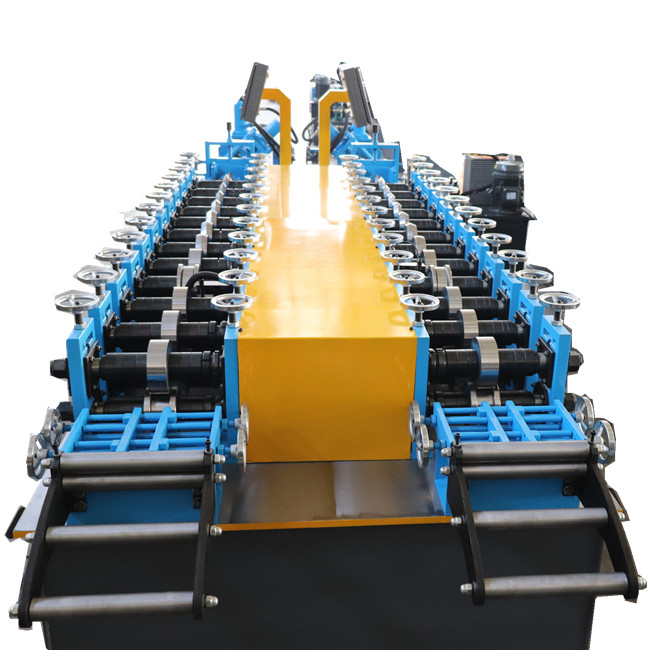

Machine Frame

|

350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate.

|

|

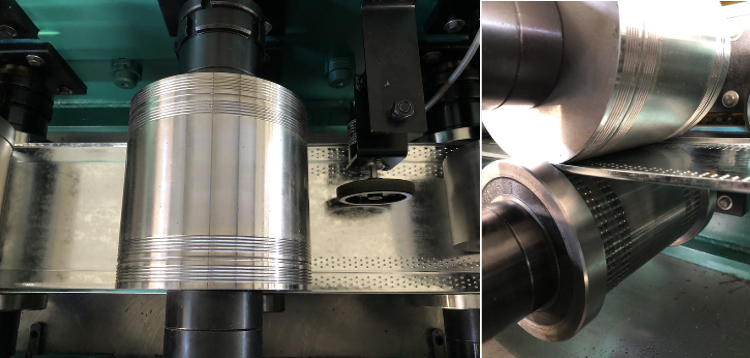

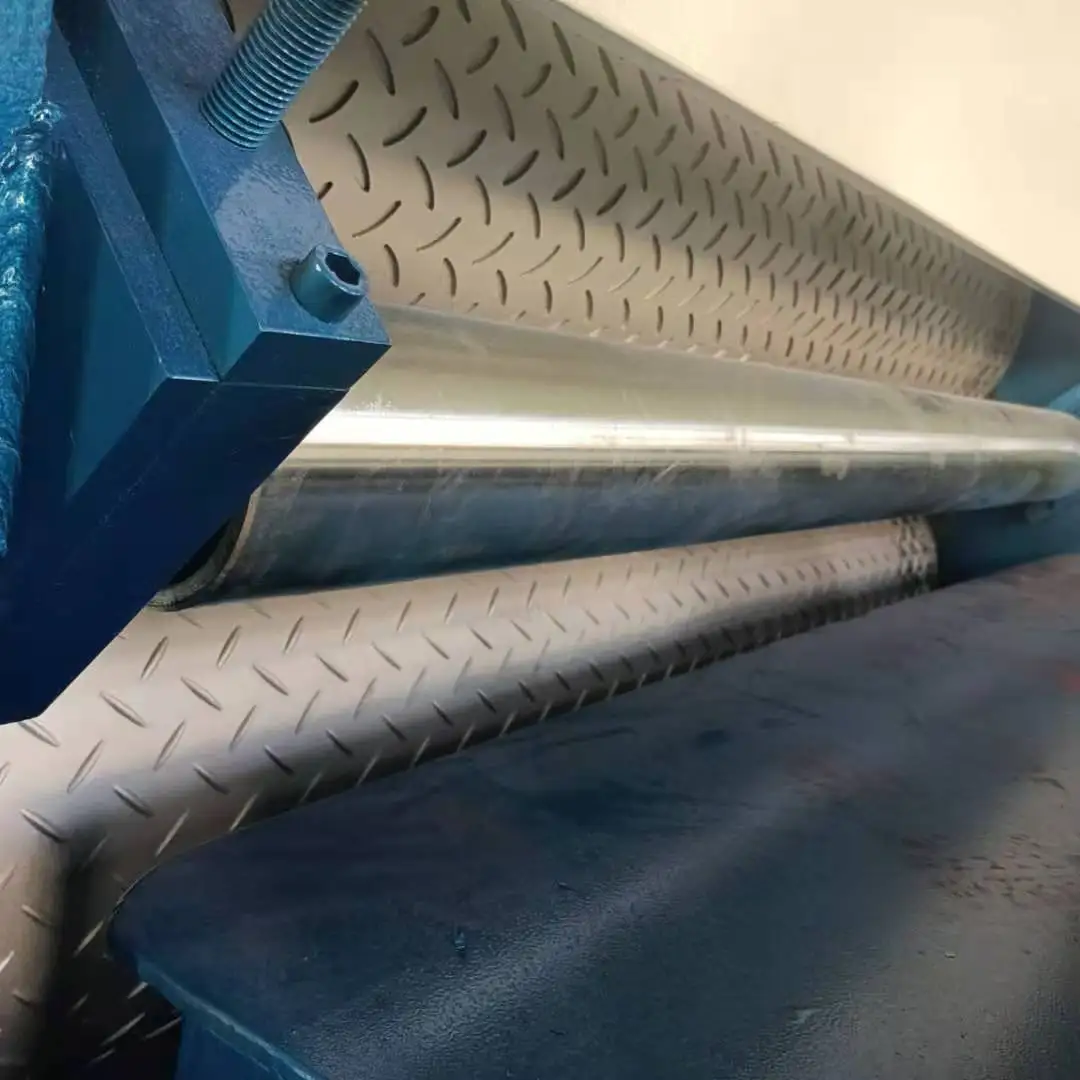

Roller Material

|

45# steel, chromed on the surface

|

|

Forming Stations

|

Roller Stations :20 Rows

|

|

Diameter Of Shafts

|

Φ80mm Solid

|

|

Material Of Shafts

|

High Grade 45#,With Heat Treatment

|

|

Forming Speed

|

15 M/Min

|

|

Voltage

|

380v/50hz/3p (As Requested)

|

|

Transmission Way

|

By 1 Inch Chain (Double Chains)

|

|

Main Motor

|

7.5 KW

|

|

Cutting Blade Material

|

Gcr12 quenched treatment

|

|

Cutting Type

|

hydraulic post cutting

|

|

Driving Method

|

By pillar type Cylinder

|

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested)

You can set orders by PLC on touch screen part, inputting product length and quantity. It is really easy to operate, and there are aviation plugs to make it much easier to install the machine when it arrives.