Fully automatic Interchange C Z purlin roll forming machine

Fully automatic Interchange C Z purlin roll forming machine could be used to make C purline, Z puline machine at the same time. The working process is fully automatic.

The working process of the roll forming machine:

Decoilerguidinglevelingroll-forming-(interchange-size-automatically) punching cut to length output table

The fully automatic Interchange C Z purlin roll forming machine is compused by the following elements: De-coiler, Forming machine, Cutting device, punching device

PLC control box, Hydraulic pump station, Production support tabl.

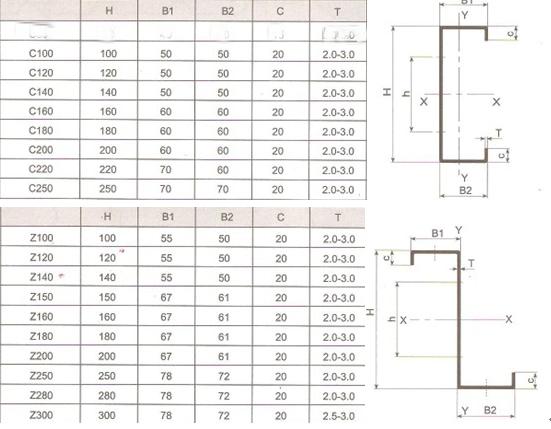

Here is the drawing profile of C purline and Z purline for your refernece:

Here is the Interchange C Z purlin roll forming machine picture:

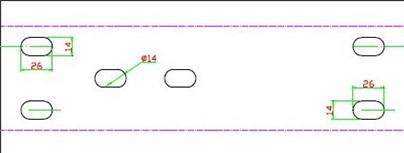

For checking main parameters of C Z purlin roll forming machine:

| S/N | Name | Parameters |

| 1 | Number of forming stations | 25 |

| 2 | Shaft material | Uses the high quality 45 steel after quenching and tempering treatment processing, the shaft diameter of 85mm. |

| 3 | Roller material | bearing steel |

| 4 | Transport | Double row chain by 40mm |

| 5 | Motor Power | 18.5Kw |

| 6 | Voltage | By customer requirements |

| 7 | Roller material | Cr12 forging steel processing after the quenching of HRC58-62. Surface blackening treatment. |

| 8 | Supported material thickness | 1.5-3mm |

When choose C Z purlin roll forming machine?

1.When worker salary is quite in some countries.

2.When firsting building factroy, it is not familiar with the operation of the machine.

3.When for C puriline and Z puline have huge production need.

4.The machine can help you finish size changing process in a few seconds. And quite easy.

5.When you have high accuracy about the finished product.

6.When you need higher speed of the machine.