Wall panel/ roofing sheet/ roll forming linear machine

Wall panel roofing sheet in metal now is quite poplar in building house, factory or temporary working places. In the normal roofing sheet roll forming machine, we only can control length but for the width, we can adjust easily. However, for some situation we need to adjust the width easily. Wall panel/ roofing sheet/ roll forming linear machine was developed based on this need. By this machine, you can make any width roofing sheet within the width 1000 to 2000mm. And meanwhile for the length you can also control by PLC.

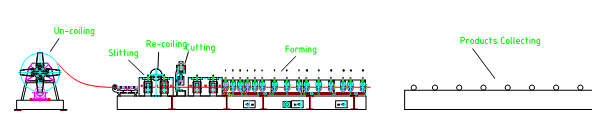

Machine working process:

Decoiler – leveling and feeding – pressure and reinforcement – roll forming machine- shearing systemrunout table

Parameters of Wall panel/ roofing sheet/ roll forming linear machine:

| No. | Item | Introduction |

| 1 | Item model | Yx7-1000-1200mm |

| 2 | Material thickness | 0.5-1.0mm |

| 3 | Control method | Mitsubishi PLC |

| 4 | Decoiler | 5 Ton normal quality |

| 5 | Rolling station number | 12 station Single side adjustment structur |

| 6 | Shearing system | One set |

| 7 | Pressure bar | One set |

| 8 | Roller material | GCR15 steel after quenching processing HRC58-62 C, chrome plated surface. |

| 9 | Shaft diameter and material | 45# steel processing, shaft diameter of 65mm |

| 10 | Main machine power | 4kw |

| 11 | Hydraulic station | 3kw |

| 12 | Hydraulic pressure | 12Mpa |

| 13 | Shearing blade material | Cr12Mov quenching HRC 58-62℃ |

| 14 | Tolerance | 3m±1.5mm |

| 15 | Electricity | 380V, 50HZ,3 phrase (customized) |

| 16 | Machine frame | Media plate |

| 17 | Transmission | By chain |

| 18 | Machine color | Yellow and blue |

| 19 | Machine size | 4.5×1.6×1.0m |

| 20 | Delivery date | 50 working days |

| 21 | Payment methods | 30% TT deposi 70% balance |

Features of Wall panel/ roofing sheet/ roll forming linear machine:

Shearing part

(1)Shearing method:It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

(2)Material GCR12 ŒQuenching Oil HRC58-62

(3)Length automatically cut in specified length

Counter Panasonic

(1) Control method: touch and button

(2) Control length automatically

(3) Production counting automatically

(4) Computer controls length and quantity for finishing production in specified amount.

(5) Fix error automatically and accurately.

Main Machine:

(1): Independent stand frame makes machine working fast speed

(2) Width adjustable by handrail then you can make any width of the sheet.

(3) Machine frame adjustable, you can adjust according to factory space.

Easy to install and easy to move