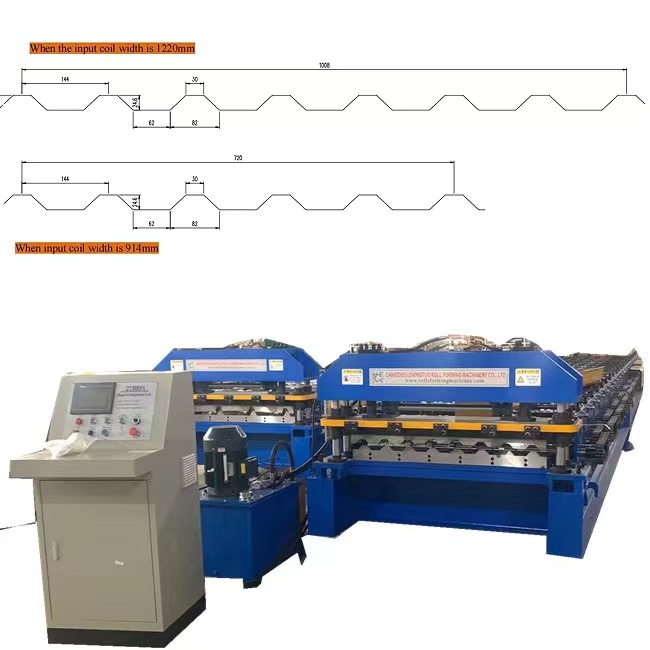

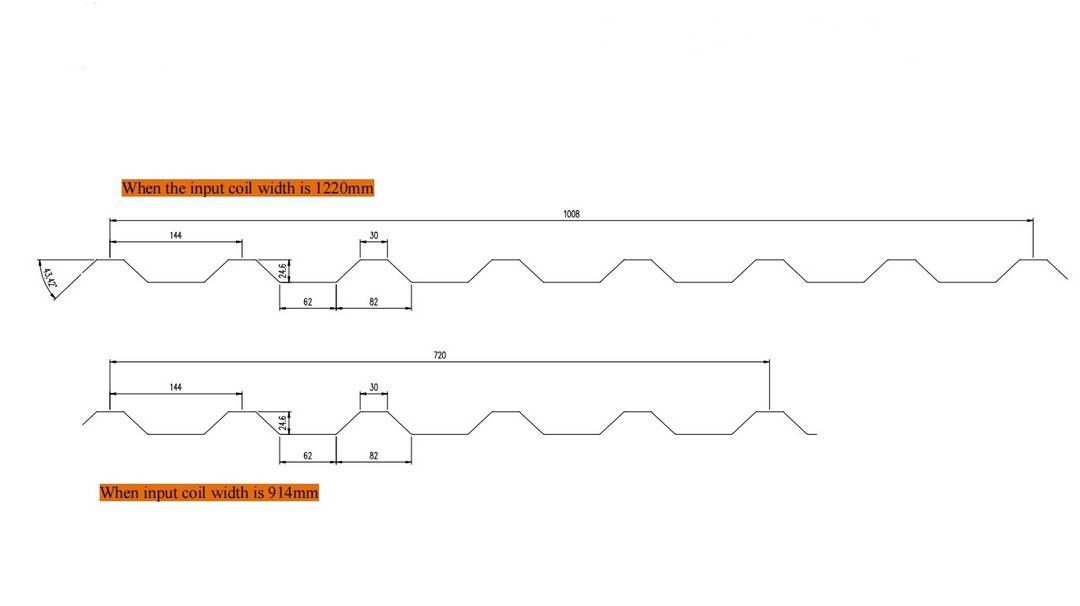

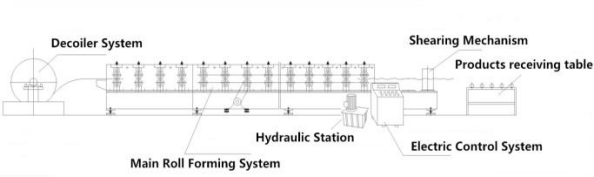

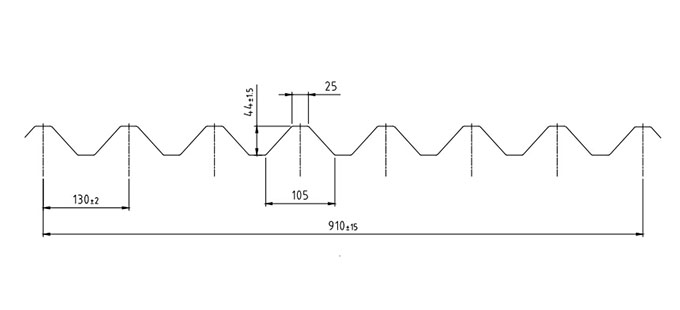

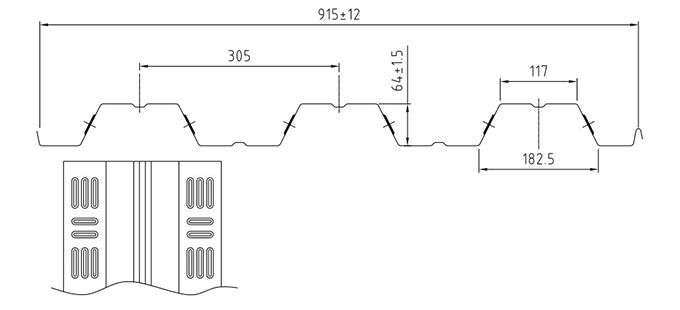

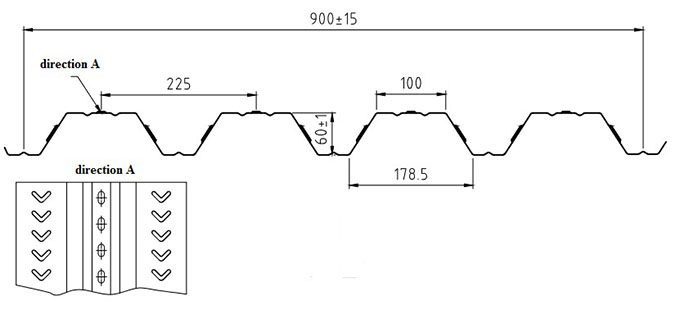

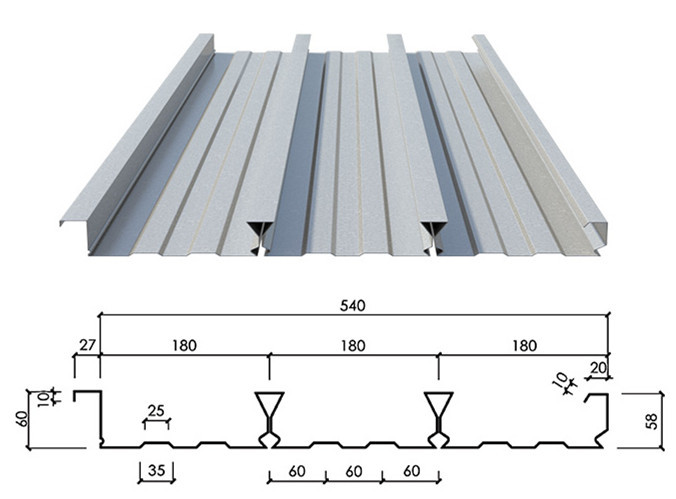

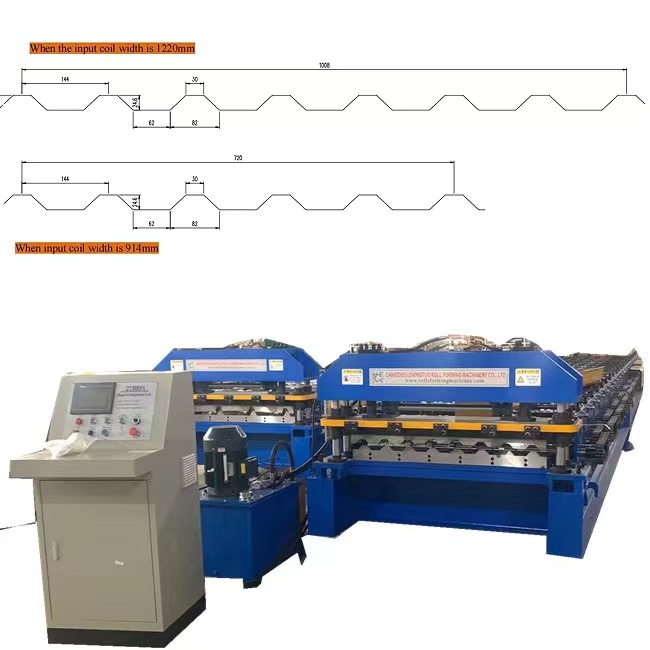

Las láminas para techos TR4 y TR5 son perfiles de techos metálicos populares utilizados en diversos proyectos de construcción. Se fabrican mediante máquinas perfiladoras que dan forma a las bobinas de metal en los perfiles deseados. Estas láminas para techos son conocidas por su durabilidad, resistencia a la intemperie y rentabilidad, lo que las hace adecuadas para diversas aplicaciones.

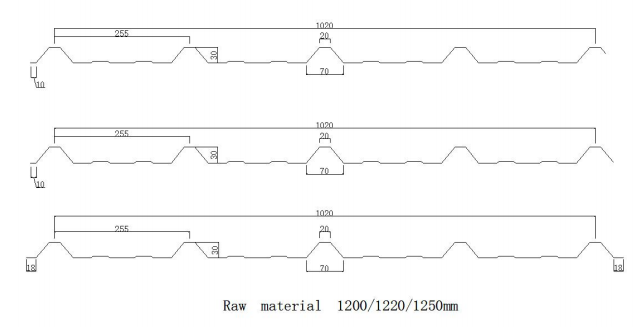

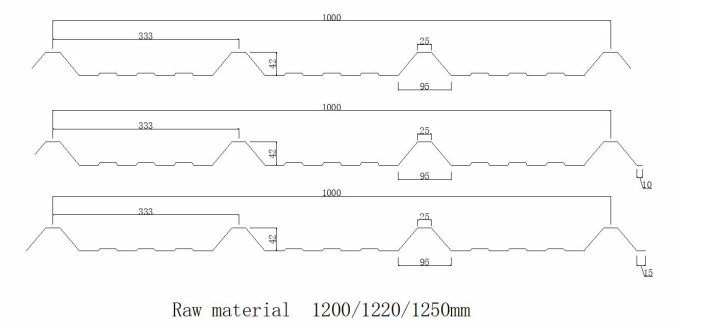

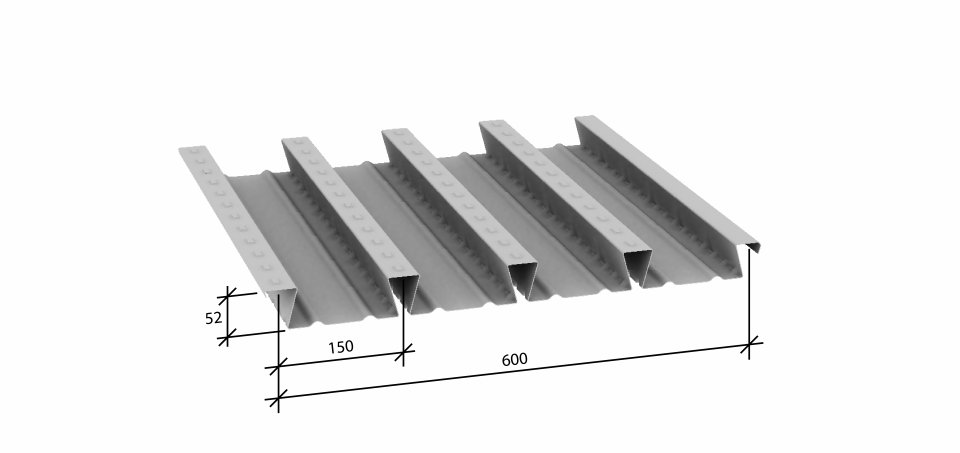

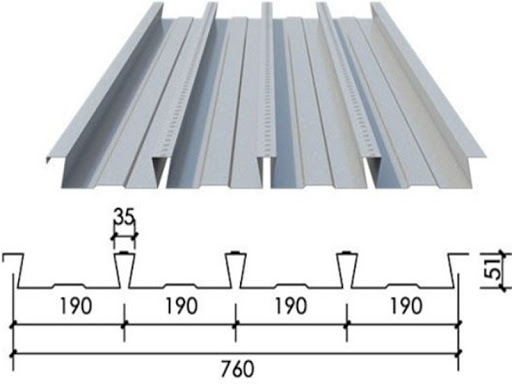

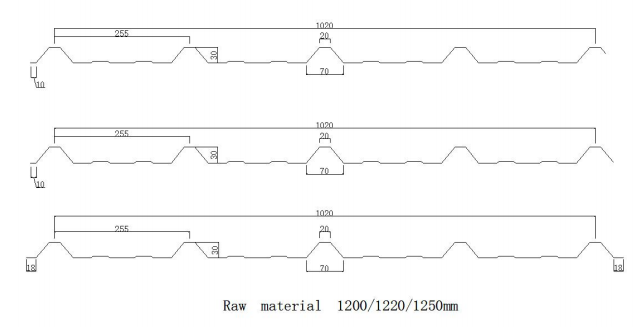

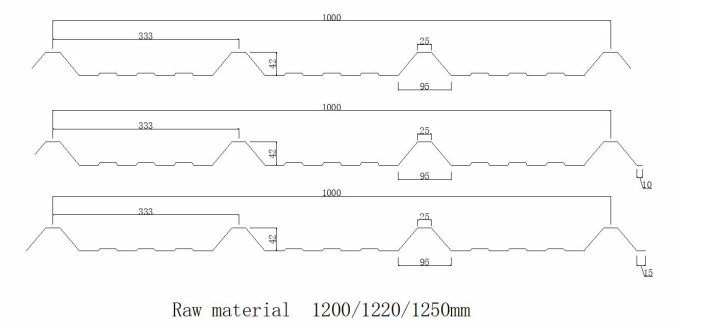

El perfil TR4 presenta una forma trapezoidal con nervaduras espaciadas uniformemente, mientras que el perfil TR5 tiene una forma trapezoidal similar con un espaciado y dimensiones de nervaduras ligeramente diferentes. Ambos perfiles ofrecen una excelente resistencia y rigidez, proporcionando una sólida solución para techos. Se pueden fabricar con diversos materiales, como acero, aluminio o acero galvanizado, y se pueden recubrir con varios acabados para mejorar su resistencia a la intemperie y su atractivo estético.

En el mercado peruano, las láminas para techos TR4 y TR5 se utilizan ampliamente en proyectos de construcción residencial, comercial e industrial debido a su versátil diseño y características de rendimiento. Se han convertido en una opción popular para constructores y contratistas que buscan una solución de techado confiable y eficiente.

La importancia de las láminas para techos en la construcción La importancia de las láminas para techos en la construcción no puede subestimarse, ya que cumplen varias funciones críticas en el diseño y rendimiento general de un edificio. Algunos aspectos clave que destacan la importancia de las láminas para techos en la construcción incluyen:

Protección: Las láminas para techos brindan la primera línea de defensa contra los elementos, como la lluvia, la nieve, el viento y la luz solar. Protegen el interior del edificio y sus componentes estructurales del daño causado por la humedad, las fluctuaciones de temperatura y otros factores ambientales.

Integridad estructural: Las láminas para techos contribuyen a la integridad estructural general de un edificio. Transfieren la carga del techo a las paredes y cimientos de soporte, asegurando que la estructura permanezca estable y segura.

Aislamiento: Las láminas para techos, especialmente aquellas con propiedades de aislamiento o diseñadas para la eficiencia energética, ayudan a mantener un ambiente interior cómodo al reducir la transferencia de calor entre el interior y el exterior del edificio. Esto resulta en un menor consumo de energía para calefacción y refrigeración, lo que lleva a facturas de servicios públicos más bajas y una menor huella de carbono.

Estética: Las láminas para techos contribuyen al atractivo visual de un edificio, ofreciendo diversos estilos, colores y acabados que pueden complementar el diseño arquitectónico. Un material de techo bien elegido puede mejorar la apariencia general de la estructura y aumentar su atractivo estético.

Durabilidad y bajo mantenimiento: Las láminas para techos de alta calidad están diseñadas para durar mucho tiempo y requieren un mantenimiento mínimo. Resisten daños por factños relacionados con el clima, plagas y corrosión, lo que garantiza que el techo siga siendo funcional y visualmente atractivo durante un período prolongado.

Rentabilidad: Las láminas para techos, especialmente las de metal, suelen ser más rentables que otros materiales para techos. Son livianas, fáciles de instalar y tienen costos de mantenimiento a largo plazo más bajos, lo que las convierte en una opción atractiva para constructores y propietarios de viviendas.

En resumen, las láminas para techos desempeñan un papel vital en los proyectos de construcción, proporcionando protección esencial, soporte estructural, aislamiento y valor estético. Contribuyen a la durabilidad, eficiencia y atractivo visual general de un edificio, lo que las convierte en un componente indispensable de la construcción moderna.

Las ventajas de las láminas para techos TR4 y TR5 para el mercado peruano

Las láminas para techos TR4 y TR5 ofrecen varias ventajas que las hacen adecuadas para el mercado peruano, caracterizado por climas diversos y una industria de la construcción en crecimiento. Algunas de estas ventajas incluyen:

Durabilidad y resistencia: Las láminas para techos TR4 y TR5 son conocidas por su excelente resistencia y durabilidad. Pueden soportar condiciones climáticas adversas, como fuertes lluvias, vientos intensos y luz solar intensa, lo que las hace adecuadas para diversas regiones de Perú.

Resistencia a la intemperie: Estas láminas para techos están fabricadas con materiales como acero, aluminio o acero galvanizado, que son altamente resistentes a la corrosión y otros daños relacionados con el clima. Con recubrimientos y acabados adecuados, las láminas para techos TR4 y TR5 pueden ofrecer una mayor protección contra los elementos, garantizando una solución duradera y de bajo mantenimiento.

Versatilidad: Las láminas para techos TR4 y TR5 son versátiles y se pueden utilizar en una amplia variedad de aplicaciones, desde edificios residenciales y comerciales hasta estructuras industriales e instalaciones agrícolas. Su adaptabilidad las convierte en una opción atractiva para diversos proyectos de construcción en el mercado peruano.

Flexibilidad de diseño: Estas láminas para techos están disponibles en diferentes materiales, colores y acabados, lo que permite a constructores y arquitectos crear techos visualmente atractivos que complementen el diseño general del edificio. Esta flexibilidad de diseño hace que las láminas para techos TR4 y TR5 sean adecuadas tanto para estilos arquitectónicos tradicionales como modernos en Perú.

Rentabilidad: Las láminas para techos TR4 y TR5 ofrecen una solución rentable, ya que son relativamente económicas de fabricar e instalar en comparación con otros materiales para techos. Su durabilidad y bajos requisitos de mantenimiento contribuyen a su rentabilidad a largo plazo.

Sostenibilidad: Las láminas para techos metálicas, como los perfiles TR4 y TR5, son respetuosas con el medio ambiente, ya que se pueden fabricar con materiales reciclados y son completamente reciclables al final de su vida útil. Además, sus propiedades energéticamente eficientes pueden contribuir a reducir el consumo de energía para calefacción y refrigeración en los edificios, lo que las convierte en una opción sostenible para el mercado peruano.

En general, las láminas para techos TR4 y TR5 ofrecen varias ventajas que las hacen adecuadas para el mercado peruano, incluida su durabilidad, resistencia a la intemperie, versatilidad, flexibilidad de diseño, rentabilidad y sostenibilidad. Estas características las convierten en una opción atractiva para diversos proyectos de construcción en el país.

En conclusión, las láminas para techos TR4 y TR5 se han vuelto opciones populares en el mercado peruano debido a sus numerosos beneficios, como la durabilidad, resistencia a la intemperie, versatilidad, flexibilidad de diseño, rentabilidad y sostenibilidad. Estos perfiles de techos atienden las diversas necesidades de varios proyectos de construcción, incluidas las aplicaciones residenciales, comerciales e industriales. La creciente industria de la construcción en Perú y la demanda de soluciones de techado confiables, eficientes y estéticamente atractivas hacen que las láminas para techos TR4 y TR5 sean una parte indispensable del paisaje de construcción del país. Como resultado, comprender las características y ventajas de estas láminas para techos es crucial para constructores, contratistas y propietarios de propiedades que buscan soluciones de techado de alta calidad y duraderas.