Steel floor decking is a type of construction material widely used in modern construction projects. It provides a lightweight and durable solution for creating floors and roofs, and it has many advantages over traditional concrete or timber structures. One type of steel floor decking is called “closed floor decking,” which has a flat bottom and no openings, making it suitable for a wide range of applications.

Closed floor decking is commonly used in commercial and industrial buildings, such as warehouses, factories, and retail stores. It is also used in residential buildings, such as apartment complexes and condominiums. The closed design of the decking makes it easy to install and connect to steel beams, and it provides a smooth and even surface for the concrete to be poured on top.

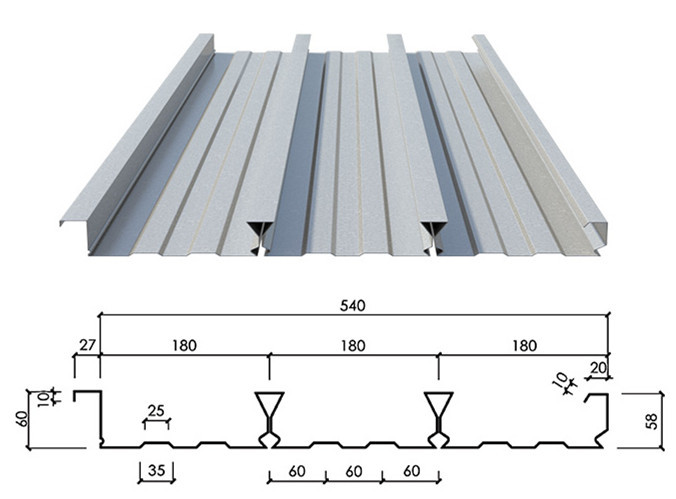

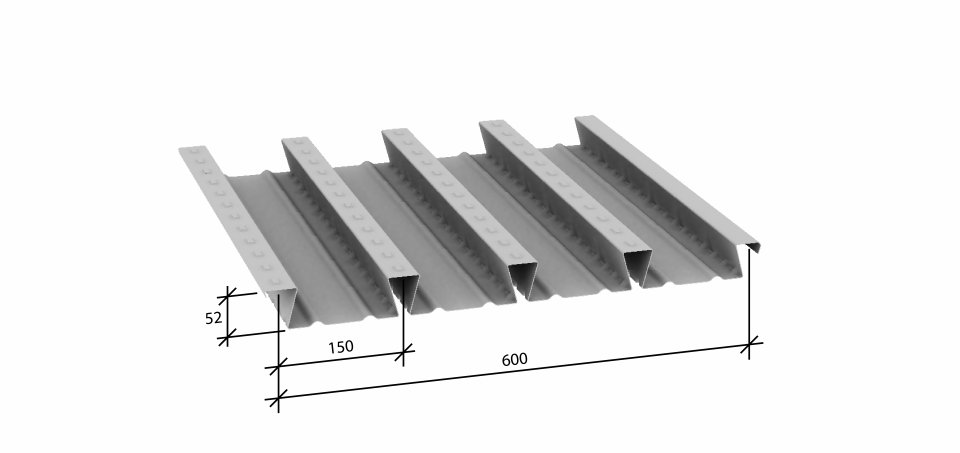

examples of closed floor deck profile:

When the closed floor deck is laid out, it only needs to be arranged in order according to the span, and when it is connected with the steel beam, it has enough contact area due to the flat bottom of the plate. Therefore, the installation process is fast and straightforward, which can help reduce construction time and labor costs.

Closed floor decking also has other advantages over traditional concrete or timber structures. For example, it is lightweight, which makes it easier to transport and install. It is also durable and can withstand a wide range of environmental conditions, such as extreme temperatures, moisture, and fire.

In addition, closed floor decking can be customized to meet specific design requirements. For example, it can be made in various sizes, thicknesses, and profiles to accommodate different building designs and applications. This flexibility makes it an ideal choice for architects and builders who want to create unique and innovative structures.

Another advantage of closed floor decking is its cost-effectiveness. Compared to other construction materials, such as concrete or timber, it is relatively inexpensive, which can help reduce overall construction costs. Additionally, it can be used to replace traditional reinforcement steel bars, which can further reduce material and labor costs.

To maximize the benefits of closed floor decking, it is important to choose the right type of decking for the project. There are different grades and thicknesses of steel decking available, each with its unique characteristics and properties. Factors to consider when selecting the right type of decking include the span of the steel beams, the load capacity of the decking, and the environmental conditions of the site.

When installing closed floor decking, it is also essential to follow the manufacturer’s guidelines and industry standards. For example, the decking should be properly supported and braced during installation to ensure it can withstand the weight of the concrete and any other loads. It is also important to seal the ends of the decking to prevent concrete from leaking through and compromising the structural integrity of the decking.

In terms of fire resistance, closed floor decking has a high fire rating, which means it can withstand high temperatures for an extended period without losing its structural integrity. This makes it a safer choice than other materials that may be more susceptible to fire damage. However, it is still important to follow fire safety regulations and install appropriate fire protection measures, such as sprinkler systems and fire-retardant coatings, to ensure the safety of the building and its occupants.

In conclusion, closed floor decking is an excellent choice for modern construction projects. Its lightweight, durable, and customizable properties make it a versatile and cost-effective solution for creating floors and roofs in a wide range of building applications. By following the manufacturer’s guidelines and industry standards, and by implementing appropriate fire protection measures, closed floor decking can provide a safe, efficient, and reliable construction solution for any project.