The reason why we called it full automatic T grid machine is that this machine could help you make T gird without person intervention, from roll forming to punching, this machine could make all perfect and fast. The machine could make main T gird in the speed of 16m/min.

The working process of full automatic main T gird roll forming machine.

Decoiler—-leveling—-roll forming machine—-punching—-cutting to length—-runout table.

Features of Zhongtuo main T grid machine:

- Full automatic and fast speed.

- Low energy consuming, no matter from workforce or electricity.

- Easy to operate, normally speaking one week then you can learn how to run it.

- The main T grid made by our machine is beautiful in shape and solid when using.

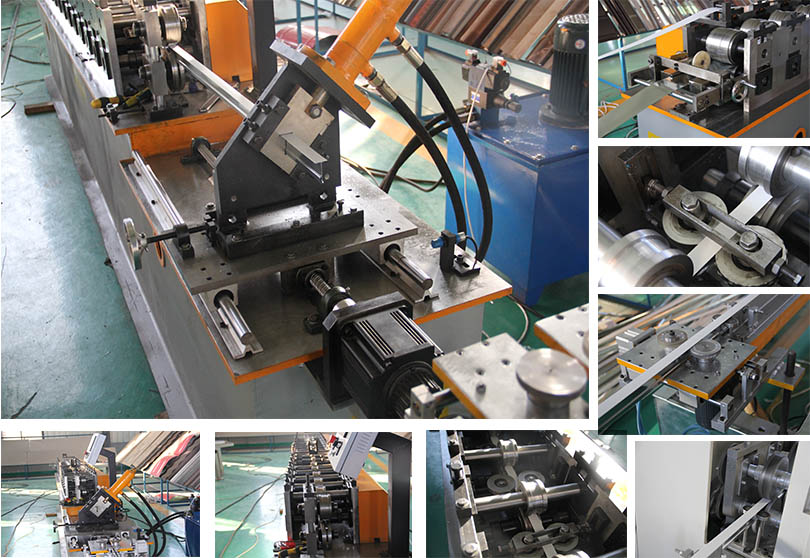

Zhongtuo fully automatic T grid machine is composed by the following elements:

- Single or double head decoiler for different types coil.

- Main roll forming machine.

- Hydraulic punching and servo cutting device.

- PLC control station.

- Runout table.

Here are some parameters of this full automatic roll forming machine for your reference:

- Number of forming rollers: 16 stations

- Shaft material: 45# steel with quenched treatment, precision machined, outer diameter: 40mm

- Roller material: bearing steel with quenched treatment

- Transport: by gear

- Forming speed: 0-30m/min

f.Motor:4kw

g.Voltage:380v, 50Hz,3 phase (make according to customer needs )

- Structure: independent stand

Automatic tracking cutting

| No. | Name | Size and mode | number | note |

| 1 | base frame | 100*100*6 | 1 | |

| 2 | Control station | 1 | Include switch button | |

| 3 | Hydraulic station | 7.5kw | 1 | Taiwan motor, low nosie |

| 4 | Oil pump | 63*80*80 | 3 | |

| 5 | Cooling device | 35Hz | 1 | |

| 6 | Sensor | Npu | 2 | |

| 7 | Encoder | 600 | 1 | Omron |

| 8 | tachometric wheel | 6 | ||

| 9 | Servo motor | 3.9kw | 1 | GSK |