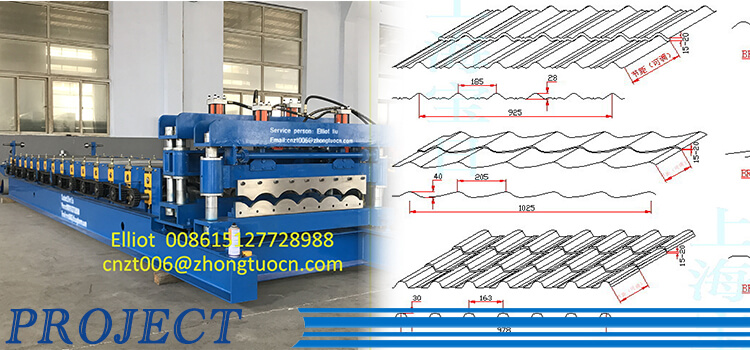

Glazed Roofing Tile Roll Forming Machine

Glazed tile roofing roll forming machine is also called glazed color steel roofing tile roll forming machine or tile roll forming machine, roofing sheet Machine, color steel roof tile machine.

Glazed Roofing Tile Roll Forming Machine application:

This type of glazed tile enjoys beautiful, classical appearance and grace taste. It can be widely used in villages, hotels, exhibitions, vocation villages, family construction and outdoor decorate.

Glazed Tile Roofing Roll Forming Machine Uncoiler System:

Usage: support steel coils and uncoil them through a turntable .

Passive uncoil pulled by roll forming system

Loading capacity: 5T

Uncoiling width: 1500mm

Inner diameter: 450-550mm

Glazed Tile Roofing Roll Forming Machine Main Roll Forming System:

Usage: Welded sheet structure, motor reducer drive, chain transmission are used to keep products in shape and precise . Rollers are chromed which allows a smooth surface of the molding plate which is not easy to be marked when stamped.

Length of the main part: about 6500х1450х1500

Weight of main part: 3.8 tons

Voltage: 380v 50hz 3 phase

Roller fixer: middle plate

Frame: 350 H steel welded

Drive mode: chain

Material of rollers:45# steel, surface hard chromium plating.

Material of shafts: 45# steel

Diameter of shafts: φ80mm

Number of rollers: 13 rollers

Main power: 5.5kw

Glazed Tile Roofing Roll Forming Machine Shearing Mechanism:

Feature : Ensure stability, precision and cutting speed

Function : Automatic cutting controlled by PLC

It employs hydraulic drive and automatic location to decide the dimension and cut target products.

Material of blades: Cr12 quenched

Power supply : hydraulic power

Components: one set of blade, one hydraulic tank and one cutter machine.

Glazed Tile Roofing Roll Forming Machine Hydraulic Station:

It is controlled by a gear pump which drives the cutter machine to cut after hydraulic oil is added into the hydraulic oil tank

Hydraulic oil: 46#

Components: a set of hydraulic tank , a set of hydraulic oil pump, four hydraulic pipes and two sets of electromagnetism valves.

Glazed Tile Roofing Roll Forming Machine Electric Control System:

1. PLC , frequency converter , Delta touch screen from Taiwan to ensure high speed yet stability, precision and lifetime.

2. Other electric element are Panasonic.

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

At ZTRFM, various payment terms are acceptable,you can choose what is convenient for you. Also we offer excellent after-sales services. Typically , we offer 1 year warranty and whole life technical support. Our engineers can work overseas and clients can also come to be trained to how to operate machines.

For more information, please contact me at Whatsapp:008618730769688 or send an email to cnzt005@zhongtuocn.com