Checker plates are widely used in our daily life and the construction industry. You can find them easily around you. And it is good business to sell checker plates. So many people are interested in buying a checker plate embossing machine and produce and sell. But before you buy the machine, you need to know some basic information about it to help you better understand it.

To make a checker plate, there are two types of machines. One is a short feeding machine set, and one is a production line including a cut-to-length line. You can use a coil roll or a short sheet to produce. If you use a short sheet to produce, the machine set only needs to include an embossing machine, a leveling machine, a feeding table, and a runout table. If you use a coil roll to produce, the line needs to include decoiler with loading car, an embossing machine, a leveling machine, a cut-to-length machine, a transport table, and a stacker.

The cost of the machine depends on several aspects: embossing pattern, material type( coil or sheet), material thickness, and width. For both types, (sheet feeding or coil feeding) the wider, the thicker the material is, the more expensive the machine is.

An embossing pattern for example:

Also here are also some other pattern examples for your reference:

Today we first introduce short sheet feeding metal embossing machine:

Its working flow is :

feeding table—embossing machine—levelling machine—runout table

steel sheet embossing machines are mainly for producing embossed aluminum and stainless metal sheets. metal embossing production line is suitable for metal sheet, particle board, decorated materials, and so on. The pattern is clear and has strong third-dimension. It can be assorted with the embossing production line

The main parts of this metal sheets embossing machine:

Feeding table– Embossing Machine—Leveling Device- Runout table

its working flow is as following:

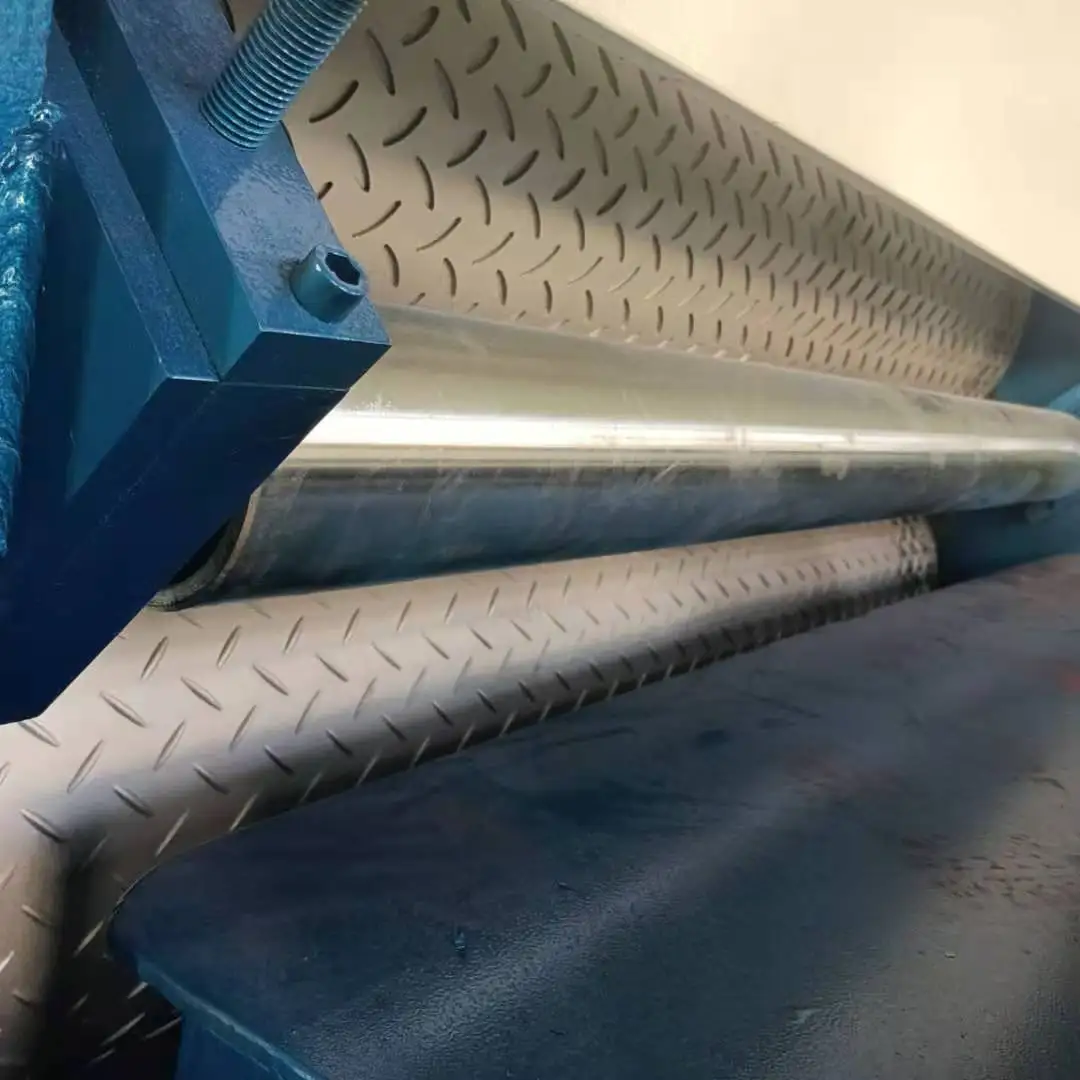

embossing machine pictures for your reference:

Leveling machine:

Embossing machine:

Embossing rollers:

Note: all the machine voltages can be customizes as your factory needs.

Normally used thickness and width combination including 3x1250mm, 4x1500mm, 6x1500mm etc.

If you need to know more about the checker plate embossing machine and inquiry , please contact me:

Sally Fu:

Whats app/Wechat:+8618730769688

cnzt005@zhongtuocn.com